Jetting of Laser Induced Cavitation in Lubricants

The collapse of a gas/vapour cavity near a solid boundary produces liquid jetting, often leading to surface damage known as "cavitation erosion." This undesirable phenomenon is commonly observed in ship propellers and turbines, but it also affects a wide range of machines and industrial installations. While the non-linear dynamics of bubbles collapsing near a flat surface in water are well understood, experimental data on jetting bubbles in liquids with different physical properties are limited. This includes highly viscous liquids, such as automotive lubricants, as well as liquids with reduced surface tensions and high vapour pressures, like typical industrial solvents or gasoline. Therefore, it is important to investigate whether "fine-tuning" the characteristics of these liquids could mitigate or even prevent cavitation erosion.

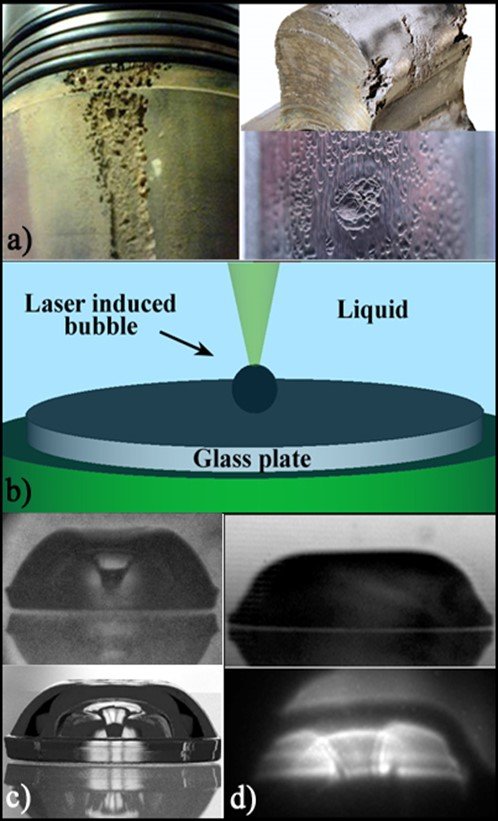

a) Cavitation erosion is commonly observed in diesel pistons, gears and bearings. (b) The bubbles are produced by focusing a nanosecond laser pulse on a glass or metallic plate. (c) Optical image (top) and simulated bubble jetting on a rigid boundary. The bubble radius is ~420 μm (d) Optical image (top) and X-ray hologram of a bubble of 500 μm forming an oblique jet.

In this thesis, we will conduct a precise assessment of the jet characteristics and potential damage resulting from laser-induced cavitation bubbles in a selection of liquids with diverse physical properties. We plan to use MHz imaging to examine the dynamics of the cavities and interpret the results with the support of numerical simulations of the bubble dynamics, taking into account not only the fluid mechanics and the acoustical aspects of the phenomenon, e.g. the generation of shockwaves on the bubble collapse.

Contact person: Assis. Prof. PhD Juan Manuel Rossello